Slot-die coating for power generation

Slot-die coating for power generation

Triboelectric generators

Society’s constantly rising electricity consumption, on the one hand, and climatic changes (global warming), on the other hand, require novel “green” approaches for energy generation. One of the emerging ways is utilizing triboelectric generators (TEG), which allow for harvesting mechanical (fluctuating surfaces due to wind or water motion) or biomechanical (human body motion) energy and converting it into electricity.

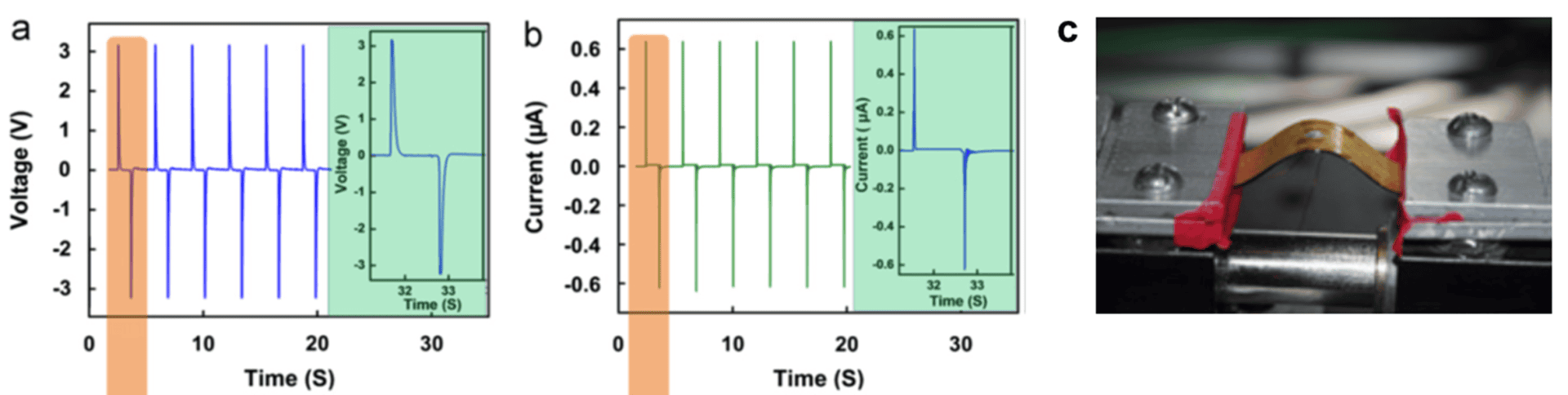

The phenomenon of triboelectricity, the formation of electric potential difference when two materials with opposite abilities to donate/accept charges are put in contact/friction, has been known for ages. However, the first successful demonstration of the TEG operation principle was published only in 2012 [1]. In this work, a sequence of electrical pulses of a few volts and several microamperes was produced by bending a simple system of two polymers in contact, Kapton, and polyester, with a given frequency. See Figure 1.

Figure 1. Electric output of TEG for (a) open circuit voltage, (b) short circuit current, and (c) picture of the tested system according to [1].

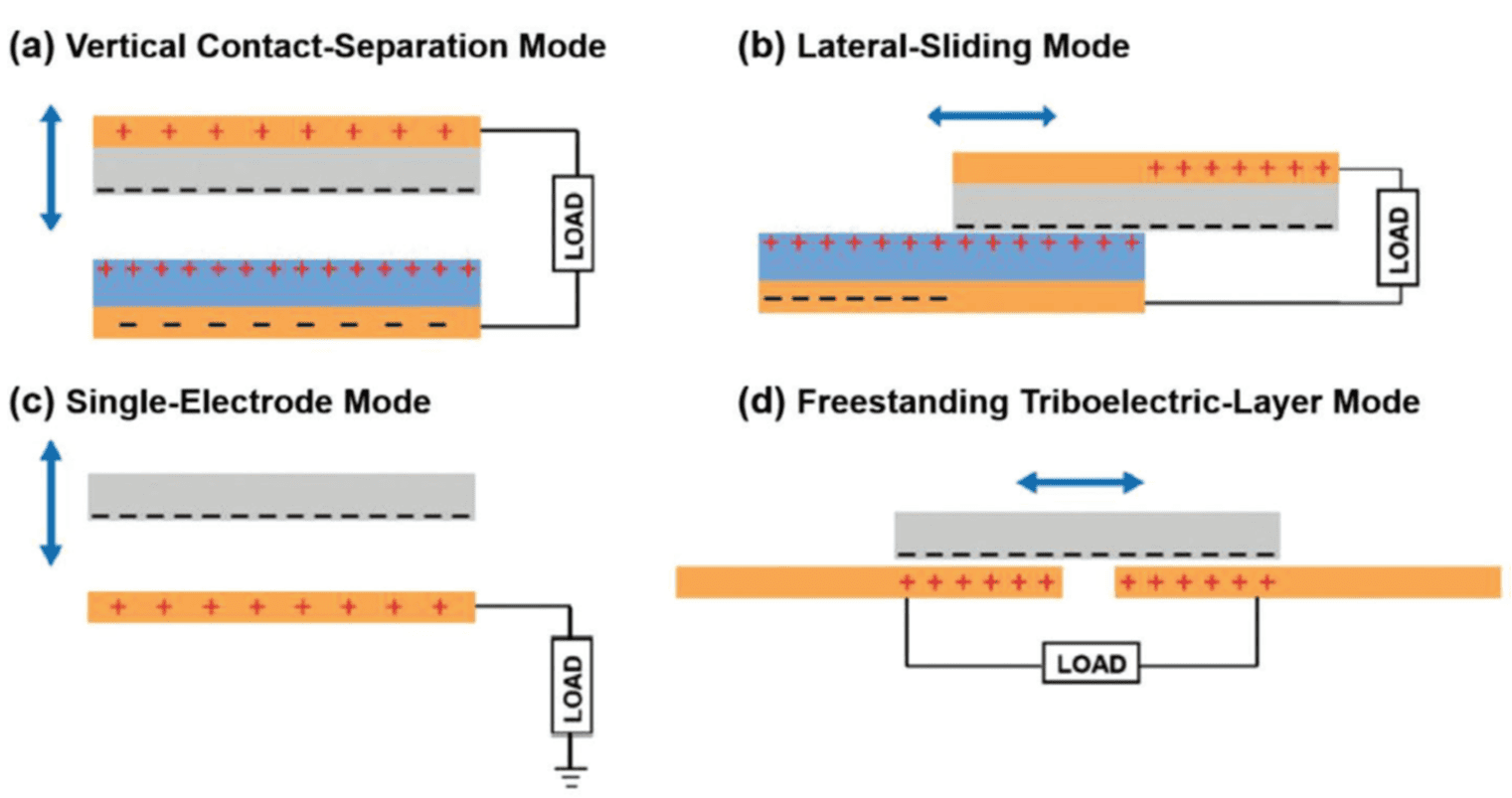

After the first publication, the TEG R&D area received a significant impetus. Figure 2 shows several typical working modes of TEGs, which were developed into portable sources of electrical current for low-power devices like light-emitting diodes and sensors used in environmental monitoring, medicine, transport, etc. [2-4]. Despite individual TEGs being able to deliver power on mW or, in best cases, on the W scale, the networks of such sources can produce a considerable amount of power.

Figure 2. Four most common working modes of TEG according to [2].

Slot-die coating of polymers

Nowadays, TEGs experience a booming period characterized by challenges with respect to materials selection, design, performance optimization, and power management. The absolute majority of TEG types utilize polymer materials for energy harvesting. Thus, the engineering of polymer films in terms of composition, morphology, and configuration is an important R&D field to resolve the challenges and produce efficient power sources. Figure 3 shows just one example of polymer film deposition. But slot-die coating is known for the production of many different types of polymer films with desired composition, thickness, and morphology, also having the advantage of being very low in materials waste. Thus, slot-die technology in general and FOM machines in particular can be an effective approach to provide solutions for TEG formation.

Figure 3. Coating of poly(arylene ether sulfone) and poly(vinylpyrrolidone) mixture by FOM alphaSC.

References

- F-R. Fan, Z.-Q. Tian, Z.L. Wang, Flexible triboelectric generators! Nano Energy 1 (2012) 328.

- A. Chen, C. Zhang, G. Zhu, Z.L. Wang, Polymer materials for high-performance triboelectric nanogenerators, Adv. Sci. 7 (2020) 2000186.

- C. Bu, F. Li, K. Yin, J. Pang, L. Wang, K. Wang, Research progress and prospect of triboelectric nanogenerators as self-powered human body sensors, ACS Appl. Electron. Mater. 2 (2020) 863.

- W-G. Kim, D.-W. Kim, I.-W. Tcho, J.-K. Kim, M.-S. Kim, Y.-K. Choi, Triboelectric nanogenerator: structure, mechanism and application, ACS Nano 15 (2021) 258.

Read more on the topic

Download the FOM Technologies Product brochure