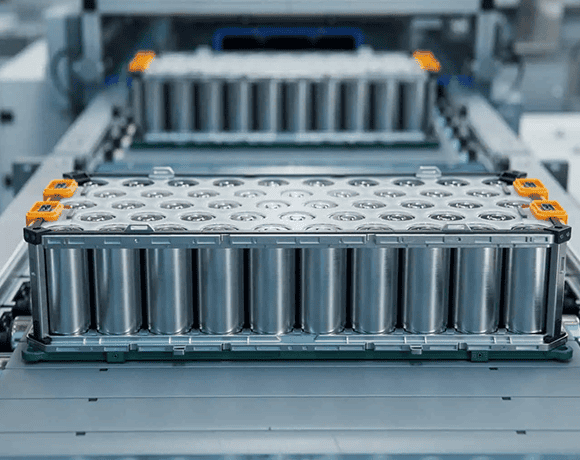

Accelerating battery innovations

Accelerating battery innovations

From lab to industry

Want to know how slot-die coating can accelerate your battery research? Download our ebook here.

Prioritizing scalability in research and development

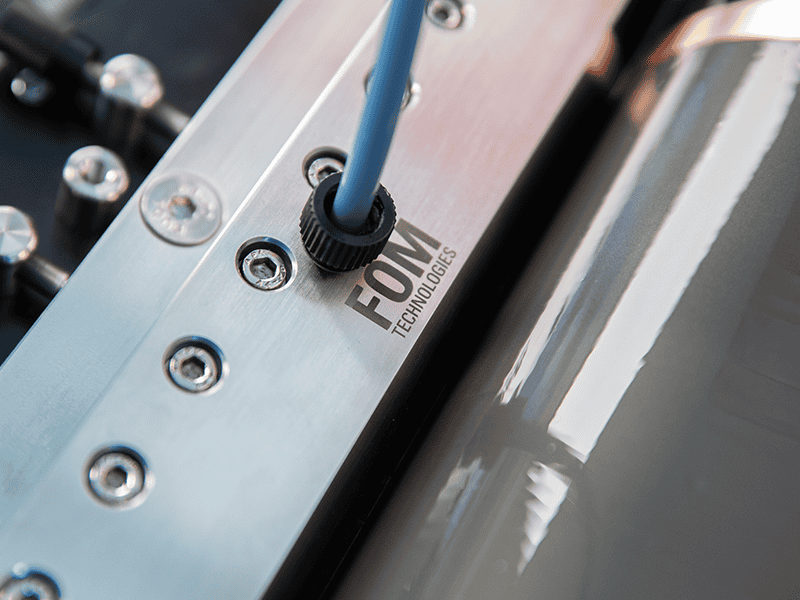

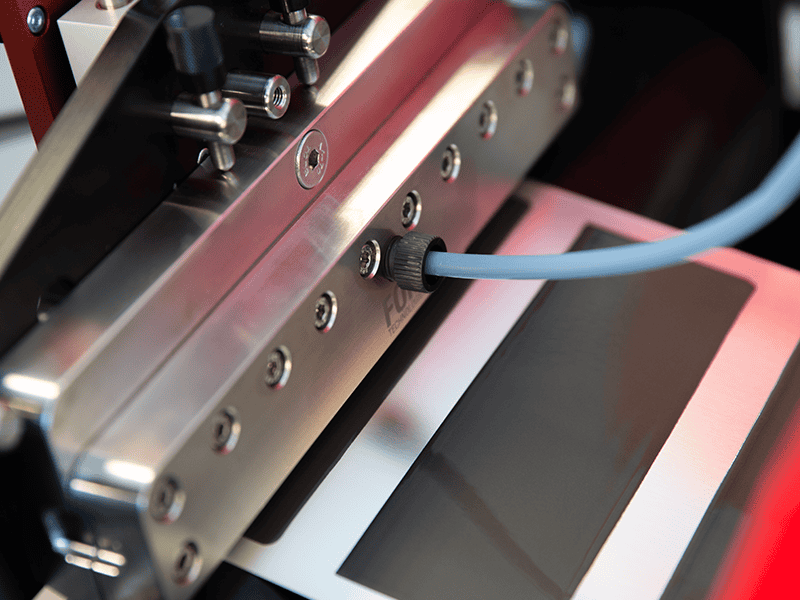

Slot-die coating technology plays a pivotal role in addressing these challenges, enabling researchers to precisely test materials under scalable conditions. FOM Technologies’ slot-die coaters are trusted by leading research institutes and companies worldwide to bridge the gap between lab and industrial scales. Our machines excel in delivering unmatched precision, repeatability, and adaptability, making them indispensable tools for battery R&D.

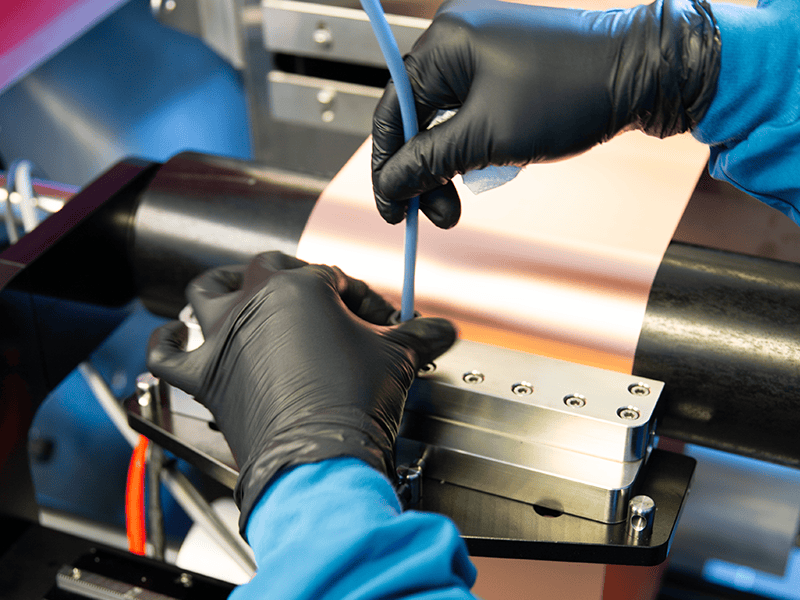

The high-precision engineering of FOM’s coaters ensures the ability to make uniform depositions without edge formation, hotspots, or other defects which are critical for testing and optimizing new electrode formulations and solid electrolytes. Repeatability guarantees that results are consistent across trials, enhancing reliability in material evaluation. Adaptability allows researchers to test diverse materials with varying properties, and investigate variations in slurry formulations, with a wide range of viscosities, making our coaters versatile solutions for evolving battery technologies.

Moreover, the pressure in academia to publish groundbreaking results can overshadow the importance of scalability. By publishing work on upscaling challenges and practical solutions, researchers can add valuable insights to the field. Novelty does not only lie in performance metrics; it also resides in developing processes that enhance yield, safety, and industrial applicability.

Many universities worldwide have already adopted FOM scalarSC or FOM vectorSC coaters in their research labs to assist researchers in developing larger and more efficient coatings of their materials. Or testing small amounts of novel materials without excessive wastage.

The importance of piloting and collaboration

Slot-die coating, a technology often used in pilot-scale R&D, excels in transitioning ideas to industrial readiness. FOM Technologies’ advanced slot-die coaters are designed to handle a wide range of functional materials, making them invaluable for battery research. Whether testing new electrode formulations or solid electrolytes, this precise and scalable coating technology ensures that researchers are equipped to evaluate real-world feasibility.

Engaging with industry early in the research process is equally vital. Researchers can gain insights into real-world requirements through advisory boards, conferences, and partnerships. Questions like “What level of material toxicity is acceptable in production?” or “How do companies handle brittle materials at scale?” can guide innovation toward practical, industry-relevant outcomes.

At FOM, we’ve created a unique modular platform that bridges lab-scale battery R&D and large-scale production. FOM moduloR2R pilot-scale system meets all the needs of a piloting phase, offering options for multiple drying ovens, precise scalability evaluation, in-depth process insights, yield assessment, and in-situ quality control.

Driving change with FOM slot-die coaters: a testimonial from IFE

As Mæhlen states, “We have been able to perform validation of battery materials in a way that is much more relevant industrially. We can also make larger casts, which allows for more throughput and better statistics.”

Marta Koposova, Senior Engineer at IFE, highlights the flexibility and adaptability of FOM’s solutions, adding, “We strongly recommend FOM tools, as they offer a unique opportunity to create industrially relevant electrodes on a more realistic laboratory scale.”

Download the free ebook:

From lab to line:

Accelerate your battery R&D with scalable slot-die coating technology

Download now

Revolutionize your battery innovation process

Discover how cutting-edge slot-die coating technology can streamline your battery research and development, reduce costs, and improve performance. Learn how to bridge the gap from laboratory experimentation to industrial-scale production with precision and efficiency.

Join industry leaders who are using slot-die technology to stay ahead of the curve in battery development.